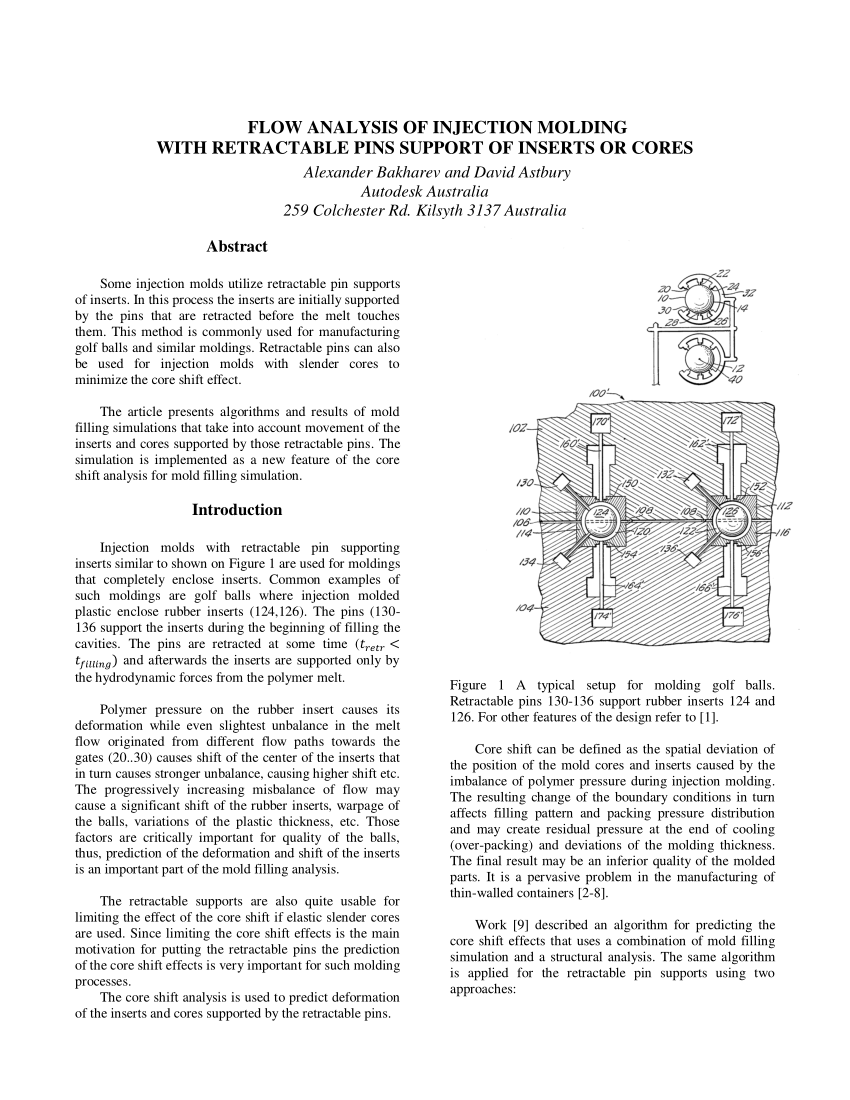

A typical setup for molding golf balls. Retractable pins 130-136

4.5 (284) · $ 26.50 · In stock

PDF) Core deflection in injection molding

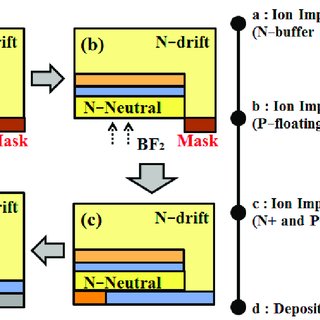

PDF) FLOW ANALYSIS OF INJECTION MOLDING WITH RETRACTABLE PINS SUPPORT OF INSERTS OR CORES

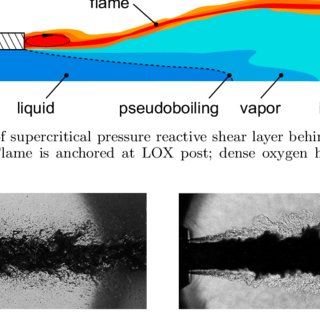

PDF) Prediction of core shift effects using mold filling simulation

PDF) FLOW ANALYSIS OF INJECTION MOLDING WITH RETRACTABLE PINS SUPPORT OF INSERTS OR CORES

A typical setup for molding golf balls. Retractable pins 130-136

PDF) Prediction of core shift effects using mold filling simulation

PDF) Core deflection in injection molding

PDF) FLOW ANALYSIS OF INJECTION MOLDING WITH RETRACTABLE PINS SUPPORT OF INSERTS OR CORES

Project design and dimensions (mm) of the specimen.

PDF) FLOW ANALYSIS OF INJECTION MOLDING WITH RETRACTABLE PINS SUPPORT OF INSERTS OR CORES

PDF) Prediction of core shift effects using mold filling simulation

Project design and dimensions (mm) of the specimen.

Case study: thermoplastic polyurethane ball

PDF) Core deflection in injection molding

PDF) Core deflection in injection molding